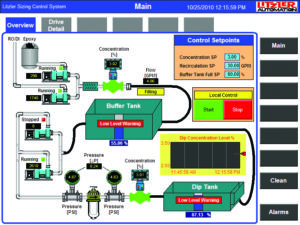

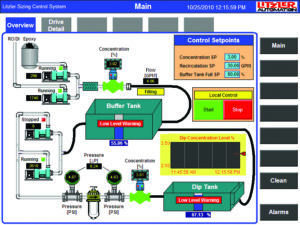

Sizing Control System

Main Screen Control

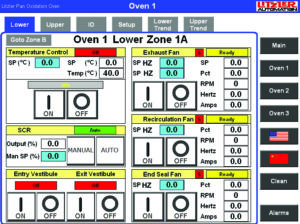

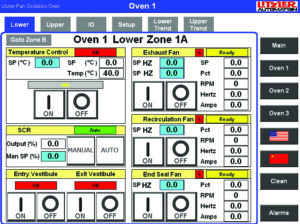

Pan Oxidation Oven

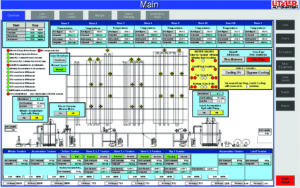

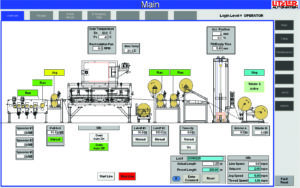

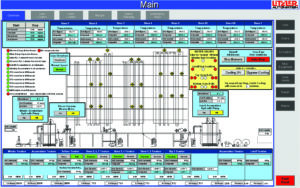

Operator Main Screen

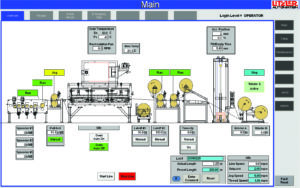

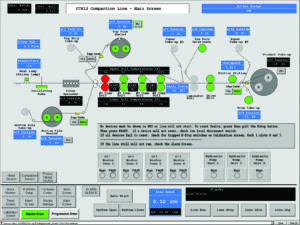

Compaction Line Main Screen

Litzler Automation

The Right Control Solutions

From the largest Tire Cord Treater to the simplest conveyor, Litzler Automation provides leading-edge control solutions for any kind of industrial application. With flexible hardware and software design using all the major control brands, Litzler Automation provides the right custom controls for your needs.

Flexible Software and Hardware Design

Our team of dedicated Automation Specialists design and build your custom automation systems using standard interfaces and software designs. We work with your current software and hardware product standards, utilizing the components you’re familiar with. The result is rapid deployment, enhanced software quality, and reliability in a system that enhances maintenance and provides a solid basis for future operation. Our flexibility makes easier upgrades, improved local support and more uptime possible.

Litzler Automation utilizes the full mechanical design and fabrication capabilities of C. A. Litzler Co., Inc. enabling us to also create the necessary mechanical systems that may be required in automation project.

Industries Served

Litzler Automation systems are used in many industries, including textile, converting, coating and laminating, composites, automotive, tire and rubber, plastics, food and beverage. Litzler brings years of experience providing solutions to manufacturers. Litzler Automation has systems in operation throughout the world.

Automation Services

- Control System Design

- Discrete and Continuous Process Control

- Electrical Schematic & Control Panel Design

- PLC/PAC Systems

- AC/DC Drive Systems

- Servo Motion Control

Control System Design

- Discrete and Continuous Process Control

- Electrical Schematic & Control Panel Design

- PLC/PAC Systems

- AC/DC Drive Systems

- Servo Motion Control

Information Systems

- Network Architecture

- Data Acquisition/Reporting

- Industrial Internet of Things (IIoT) Integration

- HMI/SCADA Systems

- Level 2 and ERP Interface

Robotics

- Part Handling and Transfer

- Vision Systems

- Mistake-Proofing/Poka-YokeETX

Vision Systems

- Mistake-Proofing/Poka-Yoke

Automation Support Services

- System Integration, Start-up & Training

- System Troubleshooting & Repair

- System Upgrades & Modifications

PLC/HMI/Drive Platforms

- PLCs/PACs – Rockwell Automation (ControlLogix, CompactLogix, MicroLogix, SLC, PLC5), Siemens (S5, S7), General Electric, Mitsubishi, Telemecanique, and AutomationDirect

- Drives – Allen-Bradley®, ABB, Siemens, Fuji, GE, Mitsubishi and Yaskawa

- Servos – Allen-Bradley®, Rexroth, Siemens, GE, AMK ETX and Mitsubishi

- HMI – Allen-Bradley®, Panelview Plus, Rockwell Software Factory Talk View, Wonderware, Siemens SIMATIC HMI, Siemens WinCC, Automation Direct C-More™, Pro-Face, Unitronix, GE QuickPanel +, and GE Cimplicity

Examples of Litzler Automation Projects

Tire Cord Treater Control Systems

- 10 Coordinated AC Drives (30-200 HP) with Tension and

- Stretch Control

- 36 Fan Drives (25-100 HP)

- 24 Servo Drives Controlling Guiding and ETX Spreading Equipment

- DC Common Bus System for Energy Savings

- 1350 Points of I/O

- 3 PLC Processors

- 6 HMI Units with Hot Back-Up System

- 30 Control Cabinets

- Complete Control System Documentation Package

Dip Molding and Coating Systems

- Single or Dual High Performance Ovens

- Single or Multiple Dip Stations

- Servo Controlled Dip Mechanism

- Automated Part Transfer

- Programmable Stored Recipes

- Flexible, Configurable Operation

Oven Systems

- Up to 60 Zone Systems

- PLC or Standalone Controller PID Loops

- Heater, Burner, Hot Oil or Steam Heating

- Infrared Heaters

- T/C, RTD, IR Pyrometer Feedback

- LEL/LFL Controls for Solvent Applications

- SCR Controllers or Burner Management

- Supply and Exhaust Fan VFD Controls

- Flame Safety Systems

- Complete Control System Documentation Package

Film Processing Lines

- 90 Line Drives

- 8 Fan Drives

- 6 Zone Heater Control Loops

- Stretch and Tension Control

- PLC System with 4 Touchscreens

- DC Common Bus System for Energy Savings

- 9 Control Cabinets

- 612 Points of I/O

- Complete Control System Documentation Package

- UL Listed

Project Upgrade – Prepreg Line

- 14 New AC Drives

- Re-Use of Existing I/O and Additional I/O Points

- Pressurized Cabinets to Protect Components from

Carbon Fiber

- Redundant HMI Systems for 100% Hot Backup

- Complete Control System Documentation Package

- Sizing Concentration System

- PLC System to Precisely Control the Concentration

- Level of a Coating in Deionized Water for Carbon Fiber

Production

- Multiple Pumps – VFD Controlled

- Sizing Concentration Sensors for ± .005% Accuracy

- P and ID Documentation

- Touchscreen HMI

- Complete Piping and Testing Prior to Shipment

- Documentation